Our Manufacturing Range

SLAV- Tablet coating High Speed Spray Gun

The sticking and build-up of deposits is prevented with the anti-beading aircap very well. The GMP design also enables a very simple installation/de-installation for cleaning or servicing by hand. This leads to shorter downtimes and more efficiency in production. Standard orifice sizes are available with 0.5 / 0.8 / 1.0 / 1.2 / 1.5 / 1.8 / 2.0 mm.

Specification

Spray pattern: oval flat spray

Spray angle: Approx. 60°

Orifices: 0.5 – 1.5 mm

Capacity: 30 – 200 g/min (coating)

Drum size: Suitable to all drum size capacity

Atomization Air Pressure: 0.7 - 3 Bar

Maximum Compressed Air Pressure:5.5 bar

Compressed Air Consumption @ 2 bar Nm2/hr Type-8.0

MOC: SS316L/ All O'ring- food grade- Viton

SLAR- Tablet Coating High Speed Spray Gun

The sticking and build-up of deposits is prevented with the anti-beading aircap very well. The GMP design also enables a very simple installation/de-installation for cleaning or servicing by hand. This leads to shorter downtimes and more efficiency in production. Standard orifice sizes are available with 0.5 / 0.8 / 1.0 / 1.2 / 1.5 / 1.8 / 2.0 mm.

Specification

Spray pattern: oval flat spray

Spray angle: Approx. 60°

Orifices: 0.5 – 1.5 mm

Capacity: 30 – 200 g/min (coating)

Drum size: Suitable to all drum size capacity

Atomization Air Pressure: 0.7 - 3 Bar

Maximum Compressed Air Pressure:5.5 bar

Compressed Air Consumption @ 2 bar Nm2/hr Type-8.0

MOC: SS316L/ All O'ring- food grade- Viton

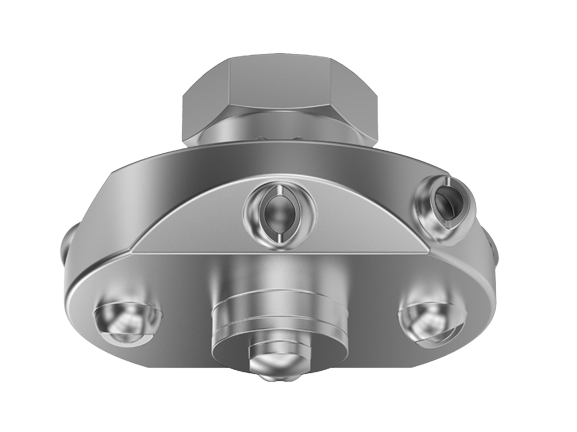

SLAS- Tablet Coatng High Speed Spray Gun

The sticking and build-up of deposits is prevented with the anti beadingaircap very well. The GMP design also enables a very simple installation/de-installation for cleaning or servicing by hand. This leads to shorter downtimes and more efficiency in production. Standard orifice sizes are available with 0.5 / 0.8 / 1.0 / 1.2 / 1.5 / 1.8 / 2.0 mm.

Specification

Spray pattern: oval flat spray

Spray angle: Approx. 60°

Orifices: 0.5 – 2 mm

Capacity: 30 – 230 g/min (Coating)

Drum size: Suitable to all drum size capacity

Atomization Air Pressure: 0.7 - 4 Bar

Maximum Compressed Air Pressure:5.5 bar

Compressed Air Consumption @ 2 bar Nm2/hr Type-8.0

MOC: SS316L/ All O'ring- food grade- Viton

SLAM- Tablet Coating Spray Gun

The SLAM is again an anti-beading / non dripping variable automatic spray nozzle Assembly is compact in size to provide solutions to even the most demanding spray application challenges for main scale production as well as for Lab Coaters. It’s easy to clean and handle. This leads to shorter downtimes and more efficiency in production. Standard orifice sizes are available with 0.5 / 0.8 / 1.0 / 1.2 / 1.5 / 1.8 / 2.0 mm.

Specification

Spray pattern: oval flat spray

Spray angle: Approx. 60°

Orifices: 0.5 – 1.5 mm

Capacity: 20 – 130 g/min (Coating)

Drum size: Suitable to all drum size capacity

Atomization Air Pressure: 0.7 - 3 Bar

Maximum Compressed Air Pressure: 5 bar

Compressed Air Consumption @ 2 bar Nm2/hr Type-8.0

MOC: SS316L / All O'ring - food grade- Viton

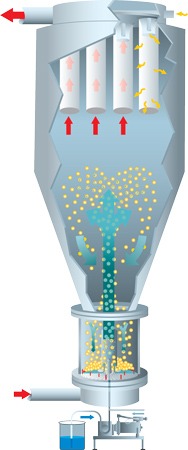

Top Spray Coating Gun

An atomizing spray gun with tri-axial wand is the standard spray gun used with for fluid bed top spray coating. Solution, atomization air and cylinder air are supplied through the spray gun assembly, creating a non-cluttered, easy to use spray gun. The number of nozzles varies depending on the batch sizes. Generally Standard head used for coatings are single.

Single Head

Multi Head

Slotted Spray Nozzles: The innovative balanced slotted design makes effective cleaning. This nozzle is made of stainless steel 316L. This nozzle is self-draining. Tailor made design, size and flow rate al so available for different process tanks .

Static Spray Ball: The new Flat spray design is used High effective cleaning in larger process vessel above 2 metre in diameter. Taylor made design, size and flow rate also available.

Accessories

Imported Products